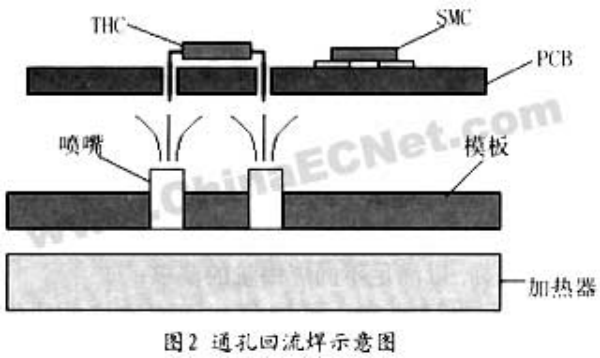

Ngokusebenzisa-hole Reflewlerling, kwesinye isikhathi okubizwa ngokuthi ukuboniswa kwezakhi ezihlukaniswe, kukhuphuke. Inqubo yokubonisa i-Pay Kweminye imikhiqizo efana nezakhi ze-SMT kanye nezinto ezihlanganisiwe (izakhi ze-plug-in) ngaphansi, lokhu kugeleza kwenqubo kungathatha isikhundla sokuthengisa amagagasi, futhi kube ubuchwepheshe bomhlangano we-PCB kwisixhumanisi senqubo. Inzuzo enhle kakhulu yokubonisa i-soldering ukuthi ipulaki ye-pay isetshenziselwa ukuthola amandla ahlangene angcono ngenkathi uthatha ithuba le-SMT.

Izinzuzo ze-Pay Relent Refleng ngokuqhathaniswa nokusebenza kwe-wave

I-1.Izinga le-Phole Reflew Soldering lihle, isilinganiso esibi se-PPM singaba ngaphansi kwama-20.

2.Ukuphazamiseka kokuhlanganiswa kwe-soler kanye nokuhlangana kwe-soler ambalwa, kanti izinga lokulungisa liphansi kakhulu.

Idizayini yesakhiwo se-3.PCB ayidingi ukubhekwa ngendlela efanayo ne-wave soldering.

I-4.Simple Process Flow, ukusebenza okulula kwemishini.

I-Eccreint-Hole Reflew Equipment ethatha isikhala esincane, ngoba umshini wayo wokuphrinta futhi uveze isithando somlilo omncane, ngakho-ke indawo encane kuphela.

6.Ng Inkinga ye-WUXI SLAG.

7. Umshini uvaleke ngokuphelele, uhlanzekile, futhi unuka ngokunuka e-workshop.

I-8through-hole Reflew Management Management and Seover ilula.

Inqubo yokuphrinta isebenzise ithempulethi yokuphrinta, indawo ngayinye yokufafaza kanye nenani lokuphrinta lihlenge ngokwesidingo.

10.Ikhohlwa, ukusetshenziswa kwethempulethi ekhethekile, iphuzu lokushisa lokushisa lingashintshwa njengoba kudingeka.

Ububi bukhole-hole Refleng Soldering uma kuqhathaniswa nokuthengisa kwegagasi:

1.Izindleko ze-Wher-Hole Reflew Soldering ziphakeme kunaleso yokudlala amagagasi ngenxa yokunameka solder.

Inqubo ye-2.through-hole Reflew kumele ibe yithempulethi ekhethekile eyenziwe ngokwezifiso, ebiza kakhulu. Futhi umkhiqizo ngamunye udinga isethi yawo yethempulethi yokuphrinta futhi ubonise ithempulethi.

3.the ngokusebenzisa umgodi ukhombisa uthando lungalimaza izingxenye ezingezona ezingashisi ukushisa.

Ekukhetheni izakhi, ukunakwa okukhethekile ezingxenyeni zepulasitiki, ezinjengama-potentiometer kanye nokunye ukulimala okungenzeka ngenxa yokushisa okuphezulu. Ngokwethulwa kwe-Phole Reflew Solleing, i-Atom ithuthukise izixhumi eziningi (uchungechunge lwe-USB, uchungechunge lwe-wafer ... njll.) Ngenqubo yokubonisa.

Isikhathi sePosi: Jun-09-2021